Drinking Water Disinfection by Ultraviolet and Preformed Monochloramine.

The Ultraviolet-installation at Lovo waterworks and effects in the distribution net.

Abstract

Stockholm Water Co. owns two waterworks, Lovo and Norsborg, and supplies water to about one million

people in the Stockholm area. Lovo waterworks, which has earlier used conventional chloramination

(consecutive addition of ammonium sulphate and sodium hypochlorite), has recently converted one of the

two production lines to Ultraviolet-disinfection and addition of preformed monochloramine. One of the reasons

for converting to Ultraviolet and preformed monochloramine was to achieve a more efficient disinfection.

Another important reason was that chlorination of the water, which has a rather high content of humic

substances, resulted in both formation of chlorinated by-products and formation of biodegradible organics

(AOC). The Ultraviolet-installation consists of two Wedeco low-pressure K-type units, each with a capacity of

3000 m3/h. Each unit has 108 lamps. Despite the great number of lamps we found the low pressure

technique more economic due to its lower energy consumption. A rather ambitious sampling and analyses

programme was set up in order to study the effects of the new disinfection strategy before deciding to

extend it to the other production line and to the other waterworks. We have had good opportunities to

study the effects of the change in disinfection strategy since only one of the two production lines at Lovo

waterworks were converted and the other continues with conventional chloramination. The two lines does

also deliver water to different parts of the distribution net. The bacterial tests were mostly focused on

heterotrophic plate count (HPC). The reduction of HPC over the Ultraviolet-units was about 3 log-units. The

HPC-numbers increases however rapidly in the pipes and tank immediately after the Ultraviolet. The tests show

that the combination of Ultraviolet and preformed chloramine does not form any measurable amounts of THM. Keywords

Drinking water, Ultraviolet disinfection, THM, AOC, Chloramine INTRODUCTION

In Sweden, the surface water treatment plants constitute only about 10 % of the total number

of waterworks but they serve approximately about 50 % of the population. Chlorine is the

most commonly used disinfectant for drinking water and chloramination is the most frequent

method used in Sweden. Groundwater is normally distributed untreated or sometimes

disinfected by Ultraviolet.

There are around one thousand Ultraviolet-installations running in Sweden, both at waterworks and

in the distribution systems. The major part of these installations are low pressure lamps

treating groundwater. In recent years, greater focus has been put on alternatives to chlorine

which has favoured Ultraviolet disinfection also for larger waterworks and other waterworks treating

surface water. WATER QUALITY AND WATER TREATMENT PROCESS IN STOCKHOLM

Stockholm Water Company supply drinking water to about one million people in Stockholm

and nine other municipalities around the city. The drinking water is treated in two large

waterworks, Lovo and Norsborg, and the total water production is about 130 million m3/year.

The raw water is taken from lake Malaren west of Stockholm. The catchment area is over

20 000 km2 and the surface area is 1140 km2 which makes the lake one of the tenth largest

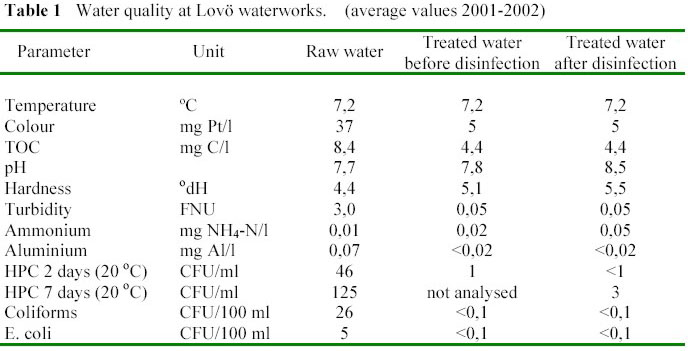

lakes in Europe (the third in Sweden). The water quality in Malaren is good (see table 1) for

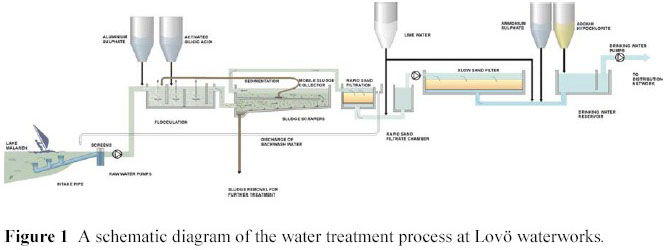

production of a high quality drinking water with the following process (see also figure 1):

screens, chemical precipitation (aluminium sulphate), sedimentation, rapid sand filtration,

slow sand filtration, pH-adjustment and disinfection with chlorine (Lovo WTP is using

sodium hypochlorite) and ammonium sulphate to get chloramine for the distribution net.

DISINFECTION STRATEGY

Lovo WTP has used cloramination as disinfection method since 1943. At the beginning

ammonia gas and chlorine gas was used, this was later changed to ammonium sulphate and

sodium hypochlorite. The chlorine dose is normally 0,5 mg/l. During the winter when the

water temperature is below 5 0C the chlorine dose is lowered to 0,4 mg/l.

After the final pH-adjustment, ammonium sulphate is added to the water and then is

hypochlorite added. This is performed just before the water enters the chlorine contact

tank/reservoir with a residence time of 45 – 60 minutes. The addition of ammonium sulphate

is adjusted to get an internal chlorine consumption of 0,2 mg/l and a residual chlorine content consisting of chloramine when the water is pumped out to the distribution net of 0,3 mg/l (0,2

during winter).

The presence of free chlorine resulting in internal chlorine consumption is important for

getting a sufficient disinfection effect but it also results in the formation of chlorination byproducts

like AOX and THM since our water has a relatively high content of organic material

(humic acids). Due to the use of chloramination the content of by-products can be kept low.

For example the THM-content is normally about 4 µg/l when using conventional

chloramination.

Even though the levels of disinfection by-products are low, the use of chlorination and the

presence of THM and other by-products is questioned, and the debate will probably not

decrease. Besides the health aspect and the consumers trust, the use of chlorine has also an

environmental aspect, for example a large part of the AOX-content of the sewage sludge

comes from the drinking water chlorination. Another drawback of the presence of free

chlorine at the disinfection is the formation of biodegradable organic substances (BDOC or

AOC).

These problems with chlorination and also a desire for a more efficient and safer disinfection

made us interested in Ultraviolet-disinfection and especially the combination of Ultraviolet and preformed

chloramine.

PILOT-SCALE TESTS

The conversion of the disinfection system started by a literature survey and pilot trials of Ultravioletdisinfection

equipment in 1998 – 1999. During the same time preformed chloramine was

manufactured and tested in the laboratory.

Some important observations from the pilot tests:

• The Ultraviolet-dose (fluence) 200 J/m2 was sufficient for our demands and gave considerably

better disinfection results than our normal chloramination. 200 J/m2 gave about 2,5 log

reduction of heterotrophic bacteria, compared to about 1 log for chloramination.

• We had virtually no scaling problems and the fouling of the quartz sleeves was negligible

even after one year of operation.

• Our low water temperature during winter (down to 1,5 0C) created problems for some of

the equipment.

• Ultraviolet-disinfection or Ultraviolet and preformed chloramine did not produce any measurable

amounts of biodegradable carbon measured as AOC whilst the AOC content increased by

almost 100% at normal cloramination.

• Preformed chloramine had little direct disinfection effect but prevented regrowth of

bacteria in Ultraviolet-disinfected water.

• Preformed chloramine did not form any measurable amounts of THM at the doses tested.

FULL-SCALE INSTALLATION

After the positive results from the pilot tests, we took the decision to commence with a fullscale

installation at the Lovo plant. The Ultraviolet equipment have been installed in one of Lovo

waterworks two production lines and a careful evaluation of the installation should be performed before any decision should be taken for installation at the other line and at the

other waterworks at Norsborg.

Stockholm Water Co. wanted to base the selection of the best system on other factors than

initial costs. As a consequence of this Stockholm Water Co. decided to calculate a Life Cycle

Cost (LCC) for each Ultraviolet installation based on a product data sheet that each vendor had to fill

in. The LCC included not only the initial cost of the Ultraviolet system but also costs for energy

consumption, maintenance, replacements of lamps, quartz sleeves and ballasts and also the

costs for piping necessary for the connection of the Ultraviolet-equipment. The variable costs of the

LCC was calculated for a time period of 20 years. Based on an interest rate of 5,5 % the

variable costs was recalculated to present worth costs. Technical criteria were evaluated for

five different factors:

- Experience of similar installations

- Lamps and sensors

- Control system

- Maintenance

- Support and service programme

Each criteria was given a score (1-5) based on certain specified aspects, the technical scores

was weighted 8 % each when the final mean score was calculated together with the LCC

score, which was weighted to 60 %.

Stockholm Water Co. invited seven vendors to propose on supply of Ultraviolet equipment to Lovo

waterworks. Proposals were received from three of them. All three vendors fulfilled the

requirements set out in the tender documents. When the scores was calculated according to

the method set out in the tender, a low pressure system from Wedeco got the highest final

mean score, and was selected for Lovo Waterworks. The low energy consumption was an

important factor to give this system a high LCC score.

THE Ultraviolet SYSTEM FROM WEDECO

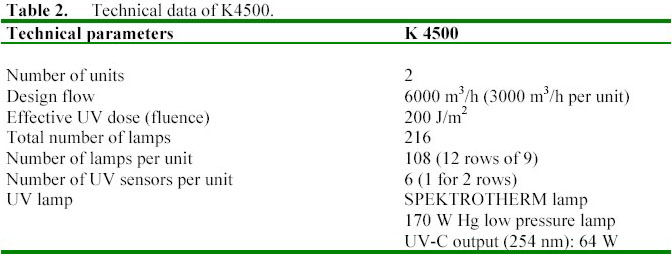

For disinfection of high flow rates of drinking water, Wedeco has developed the K-type Ultraviolet

disinfection series. These units are multiple lamp, in-line reactors with lamps arranged

crosswise to flow direction. The specific system for Lovo waterworks is called K 4500. Some

technical data is presented in Table 2. A similar K-type system is also recently installed at

Gorvaln waterworks north of Stockholm, which also uses surface water from lake Malaren.

Since we have a high bacteriological quality of the water entering the Ultraviolet-units and a rather

safe raw water supply we decided to use the Ultraviolet-dose (fluence) 200 J/m2. We were also

concerned about affecting the humic substances in the water in a negative way if using a

higher dose.

The two Ultraviolet units at Lovo was installed in an existing space between the incoming pipes from

the slow sand filters and the original chlorine contact tank/reservoir. The space for installation

was limited, so each Ultraviolet unit had to be built in four sections with flange connections.

The Ultraviolet units was installed during August-September 2001. The performance requirements

set up in the tender included:

- inactivation tests of the natural heterotrophic bacterial (at least 2,5 log reduction by our

modified 2-day HPC method)

- guaranteed energy consumption at normal (3000 m3/h) and maximum water production

(6000 m3/h)

- pressure head loss of maximum 0,15 bar at 6000 m3/h

The Ultraviolet-units was started in October 2001 but conventional chloramination was used together

with Ultraviolet until September 2002.

PRODUCTION OF PREFORMED CHLORAMINE

Preformed chloramine is produced by reacting sodium hypochlorite and ammonium sulphate.

The pH and the concentration of the solution is important both for getting monochlormine

(which is the preferred product) and for the stability of the chloramine solution.

Our production facility is built for batch production of chloramine and is designed for full

production at both production lines of the waterworks. The same hypochlorite and ammonium

solutions is used as for conventional chloramination. Sodium hydroxide is used for the pH

adjustment.

The produced chloramine solution contains about 1 g Cl2/l and has a pH-value between 9 and

10. The dose of chloramine to the drinking water is 0,2 – 0,3 g Cl2/m3 to keep the chlorine

residual at about the same level as it was with the conventional chloramination.

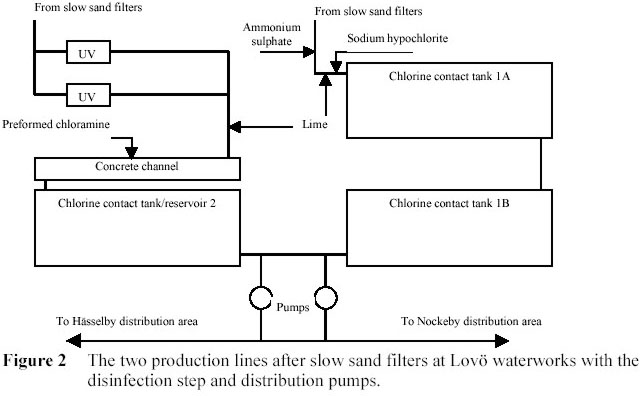

WATERWORKS AND PIPE NETWORK

After the slow sand filters the Lovo waterworks is divided into two separate production lines

for disinfection and pH-adjustment. Each of the production lines have a production capacity

of 6000 m3/h and a normal production of about 3000 m3/h. One of the lines is converted to

Ultraviolet and preformed chloramine and the other continues with conventional chloramination.

The production lines does to a large extent deliver water to different parts of the distribution

network. This gave us a good opportunity to compare the two disinfection methods. The area

receiving mainly Ultraviolet-disinfected water is referred to as “Hasselby area” and the reference

area receiving conventionally chloraminated water “Nockeby area”. There is usually a certain

degree of mixing of water between the two areas depending on which pumps that are used. It

is usually well below 20% of the delivered water to each area that comes from the other

production line.

Besides the normal control programme for sampling and analyses in the network, four

sampling points have been used in the respective area. This points represents different

distances from the waterworks (or different age of water). Samples have also been taken

where the water leaves the waterworks to the two areas.

As a part in the evaluation of the disinfection method the formation and growth of biofilm in

the network is specially studied by a Ph.D. student at the Swedish Institute for Infectious

Disease Control. Within this project the bacterial species in the water and biofilm will be

identified.

ANALYSES

The heterotrophic plate count (HPC) 2-day analysis was modified to obtain a higher

sensitivity. Water samples (10 – 1000 ml) were filtered with black 0.45 µm filters (Sartorius

Cellulose Nitrate filter) and the filters were placed on petri plates with R2A agar. The plates

were incubated for two days at 20 0C. For the 7-day HPC analyse 1 – 5 ml of sample was

mixed with R2A agar and incubated for seven days at 20 0C.

At the regular analyses in the network Stockholm Water Co. uses 7-day HPC according to

Swedish standard SS028169-2, which incorporates yeast peptone agar, 1 ml of sample and

20 0C incubation.

The AOC analyse was performed by the Swedish Institute for Infectious Disease Control

(SMI) accordning to the method MB040B00.V03, which is a slight modification of the AOC

procedure that initially was developed by Van der Kooij. Pseudomonas fluorescens strain P17

was used in these measurements.

THM were analysed by the Swedish accredited laboratory Sweco Ecoanalys. THM (sum of

chloroform, dichlorobromomethane, chloro-dibromomethane and bromoform) were analysed according to the standard EPA 524.2. All samples were delivered to the laboratory the same

day as they were taken.

Results

We are still in a quite early stage in the evaluation process and therefore are the results and

conclusions following often preliminary.

Acceptance tests

At the acceptance tests of the Ultraviolet system in October 2001 the installation passed the tests in

most respects but failed in the most important, the bacterial inactivation. Since the installation

incorporated 900 bends in the pipes just in front of the reactors, the flow pattern was suspected

as being the cause of the unexpected low bacterial reduction.

After installation of baffle plates in the inlets to the reactors a new series of inactivation test

was performed and this time the installation passed the test. The log reduction was between

2,6 and 3,1.

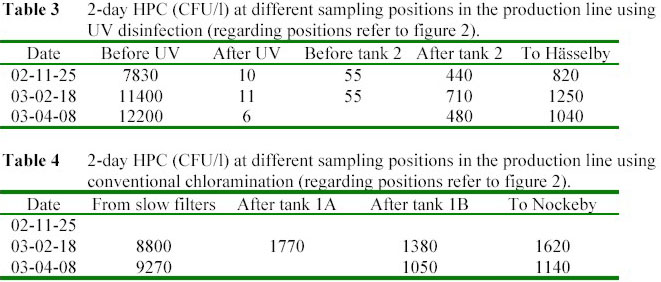

Bacterial quality in the waterworks

Knowing that our Ultraviolet disinfection had a much greater reduction in HPC-bacteria than the

conventional chloramination we were surprised by the small difference in HPC-numbers at

the end of the two production lines. To investigate this, samples were taken at different

positions in the production lines, the result is shown in table 3 and 4. As can be seen there is a

large reduction over the Ultraviolet, but after that the HPC-numbers increase. This could perhaps be

explained by release of bacteria from the biofilm in the system, but the increase is surprisingly

large and has to be further investigated.

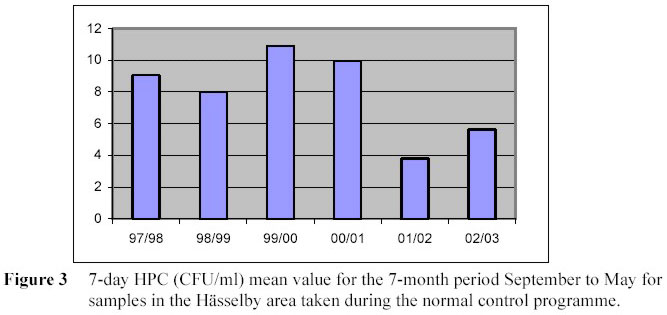

Bacterial quality in the distribution net

The combination of Ultraviolet and preformed chloramine have now been in use in the Hasselby

production line for seven months (02-09-10 to 03-05-10). During that period about 35

samples taken in the Hasselby area have been analysed for 7-day HPC during the normal

control programme for water quality. This values have been compared with analyses from the

same area and seven month period during earlier years (Figure 3). In the period 01/02 Ultraviolet was used in combination with conventional chloramination. The HPC-numbers have decreased

since the installation of Ultraviolet but it is to early to draw any conclusions from this limited data.

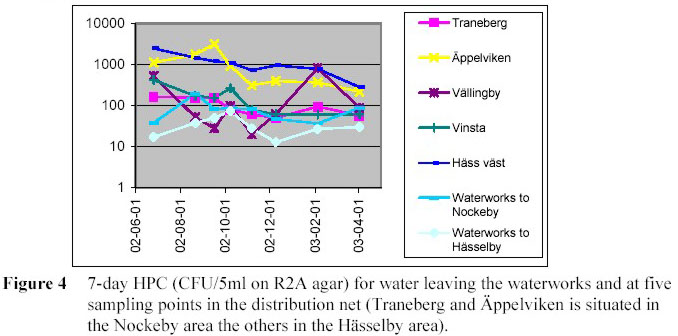

Besides the normal control programme, eight sampling points have been selected (four in

each distribution area) and are specially studied. 7-day HPC on R2A agar is among the

analyses made on these samples. The results from five of the points in the network and the

two points at the waterworks is shown in figure 4. So far, there is nothing indicating any

obvious differences between the two areas regarding the development of the bacterial quality

in the two areas.

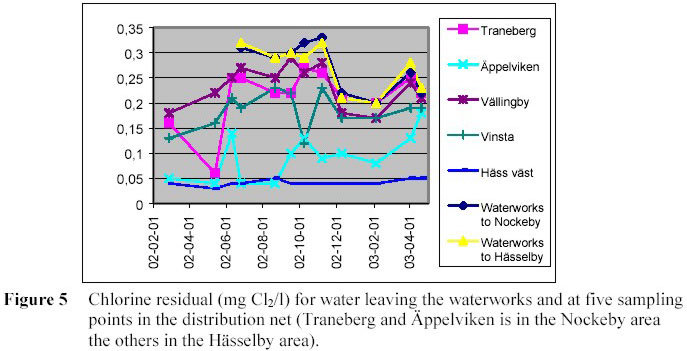

Chlorine residual

Before the change of disinfection method, there was some worry that the chlorine residual

should decrease faster when using preformed chloramine since the humic acids had not been

oxidised or chlorinated as in the case with conventional chloramination. The data collected so

far does not support this theory. The chlorine residual appears to be equally stable as with

conventional chloramination (Figure 5).

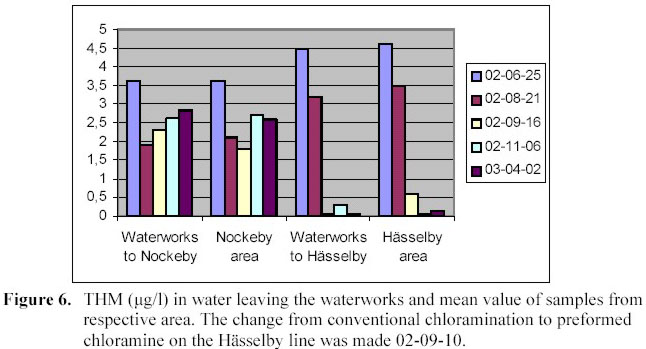

THM

The results shows that the formation of THM when using Ultraviolet and preformed chloramine is

negligible (Figure 6). The small amounts measured is probably due to a small intermixing of

water between the production lines.

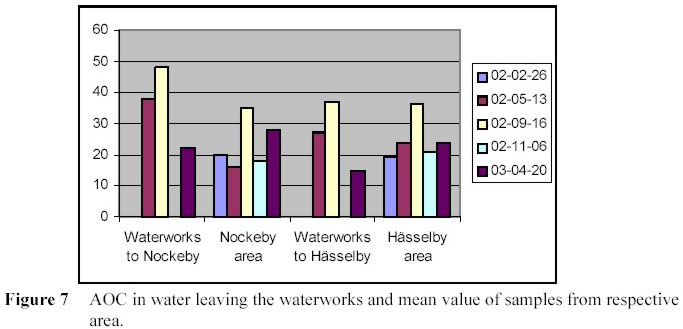

AOC

It has earlier been shown that our conventional chloramination generates AOC due to

oxidation of humic substances and that this is not the case when using preformed chloramine.

This was also shown in our pilot scale tests. The data from the full scale seems to support this

for the water leaving the waterworks. There is however no significant difference between the

two distribution areas (figure 7).

CONCLUSIONS

When we made the change from our conventional chloramination to Ultraviolet light and preformed

chloramine, we hoped to achieve the following three advantages:

- Less formation of chlorinated organic by-products

- A more safe and effective disinfection

- Less regrowth of bacteria in the distribution system due to lower AOC levels

We have, as shown above, fulfilled the first two expectations. Regarding the third we can, by

using Ultraviolet and preformed chloramine, achieve lower AOC levels at the waterworks but if the

conclusions from the limited data above is correct, there is no difference in AOC further out

in the distribution net.

This difference on AOC at the waterworks and in the distribution net could perhaps be

explained by assimilation of AOC by the micro-organisms in the water and biofilm to a kind

of balanced steady-state level of AOC. The risk for regrowth of bacteria, in the parts of the

network were the chlorine residual is low, is probably equally large for both disinfection

methods. The risk for bacterial growth containing pathogenes is however probably smaller if

using Ultraviolet and preformed chloramine due to a more efficient disinfection and then a more

effective barrier to protect the network from intrusion of pathogenes.

Ulf Eriksson, Inga Nordwall

Research engineer, Stockholm Vatten AB, S-106 36 Stockholm, Sweden

Chemist, Laboratoriet Stockholm Vatten AB, Lovo vattenverk, S-178 93 Drottningholm

|